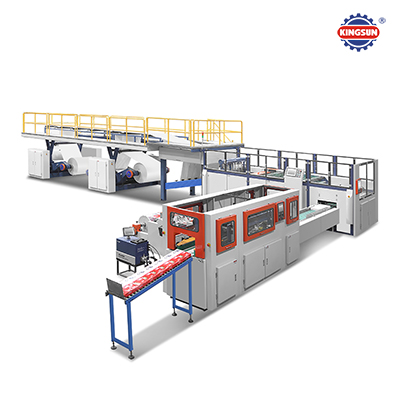

The common type of paper slitters consists of machine frame, transmission system, unwinding and rewinding mechanism, web guide and tension control device, traction system, slitting knife holder, waste edge rewind and discharge device, so the slitting adjustment need more manually and experience.

With the

development of new technology, the new paper roll slitters now adopt more

advanced control system and better design structure, servo control or frequency

conversion motor drive, PLC and touch screen control to achieve automatic

tension controlling, high speed working, smooth rewinding roll edge surface,

and nice paper rewinding tension. Kingsun paper slitting and rewinding machine

adopts world famous brand components, stable and reliable, we can customize the

paper roll slitting machine to meet your special material cutting needs.

We combining the

latest technology with our factory 30+ years of manufacturing experience, to

research and manufacture high quality paper slitters, we have over 50 different

models of slitting machines to fit for slitting kraft paper, cardboard paper,

thermal paper, craft paper, adhesive label paper etc, our paper slitter

rewinders sold to 70+ countries and we continue to develop more advanced

slitting machines to meet various customer’s requirements, our selling price is

most competitive but with high quality and world level after sale service, so

it is well accepted by slitting converting company around the world.

If you are looking for a jumbo paper roll slitter machine? We are always ready here for providing you the best slitting machines and services, contact us now!

Don’t see the model of paper slitter what you’re

looking for here?

Please contact us to talk about your specific slitting machinery needs, welcome to custom made.