The KMHK series fully automatic die cutting machines can efficiently complete the die cutting and embossing of products,as well as maintaining the highest precision and product quality.

KMHK-1050/KMHK-1050CE Model Fully Automatic Die Cutting Machine with Stripping

The MHK series fully automatic die cutting machines can efficiently complete the die cutting and embossing of products,as well as maintaining the highest precision and product quality.The MHK series full-automatic/hot foil stamping/stripping/creasing die-cutting machines are well equipped and almost can adapt to all die cutting requirements of products.

Main features:

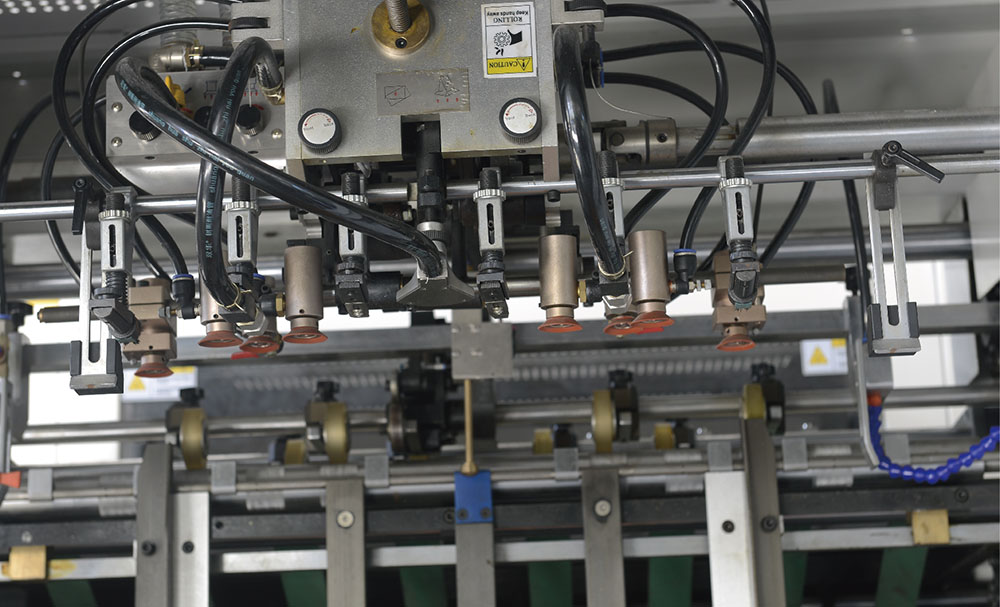

1. High quality feeder made in Taiwan with 4 suction nozzle for stack paper and 4 suction nozzle for delivering paper , ensures stable and fast paper feeding .

2. Pre-loading unit , non-stop feeding , with Max pile height to 1600mm.

3. The pre-loading unit is equipped with guiding rails , operator move the stack paper to feeder accurately and conveniently .

4. Side and front guiding have sensor which can adjust the sensitivity.

5. The anti-obstacle device prevent the machine damaged.

6. Paper feeding will be slow down when the paper reach the front guiding , achieve more accurate location .

7. Japanese NITA convey belt , the speed can be adjusted .

8. Germany made stainless steel is used for convey board in order to achieve smooth and quick paper delivery .

9. Pneumatic cutting plate lift for easy slide in and out .

10.Easy way to turn over and change die cutting chase and plate with short time .

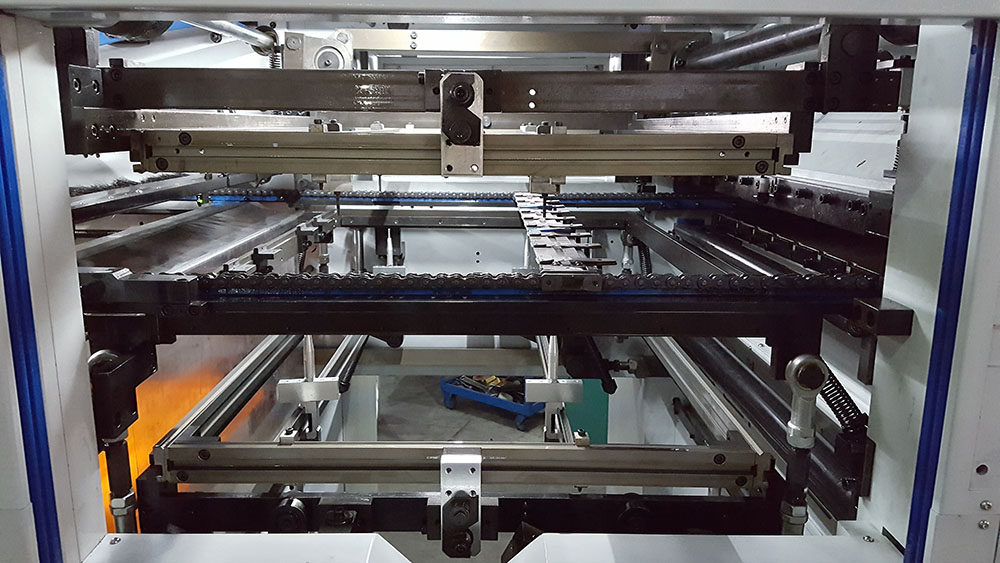

11.High quality gripper bars made in Japan with long life time .

12.High quality U.K imported chain ensure stability and accuracy in long time running .

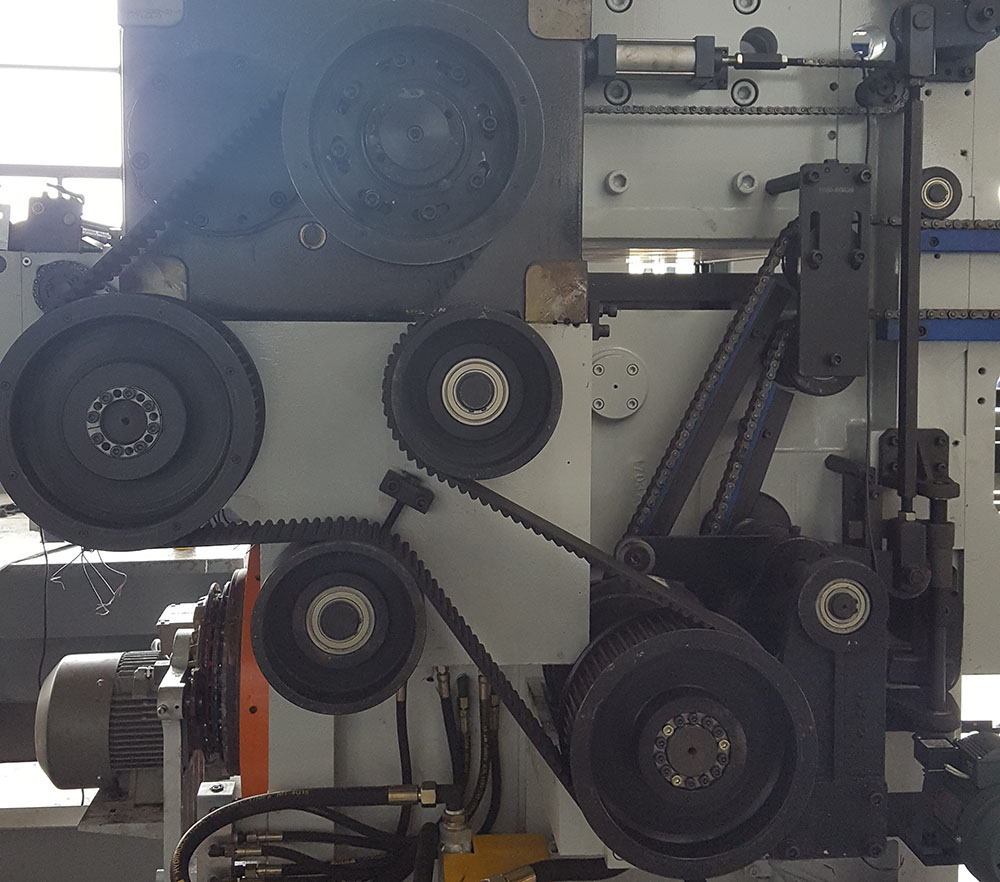

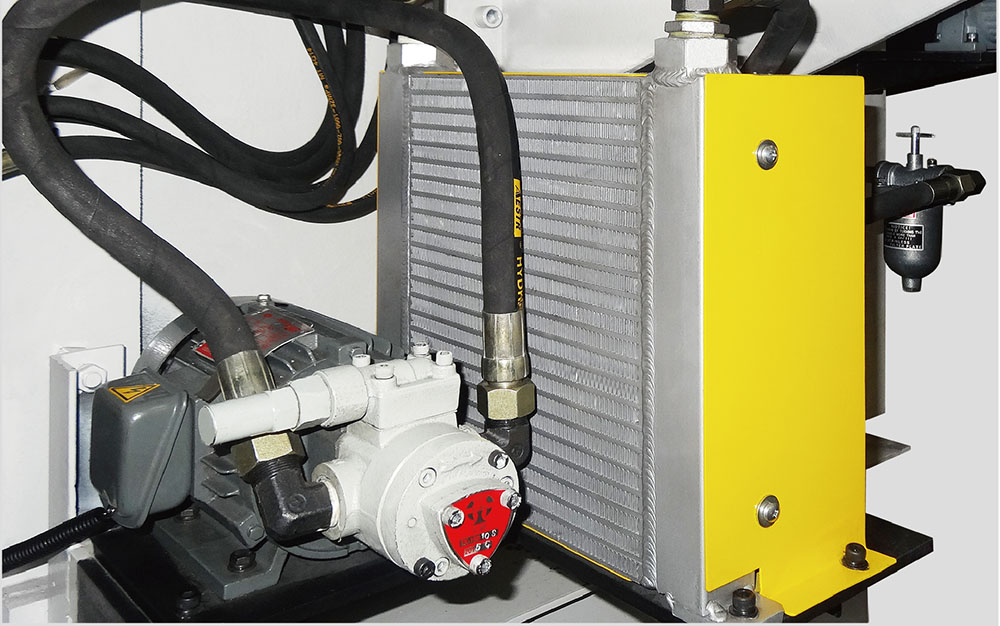

13.Automatic lubrication and cooling system for main drive and automatic lubrication for main chain .

14.Overload protection device with torque limiter in index box for the highest safety of operator and equipment .

15.Crank shafts and worm rod is made of 40 Cr with heating handling . Turbine is made of copper .

16.High quality imported air clutch .

17.SMC pneumatic components .

18.The upper , middle and lower stripping frames are controlled by 3 GPRS of cam wheels respectively.

19.Match with the center-line registration system in die cutting unit , the same system also apply to the stripping station to minimize changeover time , Accurate positioning can increase production efficiency.

Main technical specifications:

| Model | KMHK-1050T/TC | KMHK-1050 | KMHK-1050CE |

| Max.Sheet size | 1050*750 mm | 1050*750 mm | 1050*750 mm |

| Min. Sheet size | 400*360 mm | 400*360 mm | 400* 360 mm |

| Max.Die cut size | 1040*720 mm | 1040* 720mm | 1040*720 mm |

| Max Hot stamping size | 1040*720mm | no | no |

| Inner chase size | 1080*745mm | 1080*745 mm | 1080*745 mm |

| Paper thickness |

80-600g/m2 corrugated less than 4mm |

80-600g/m2 corrugated less than 4mm |

80-600g/m2 corrugated less than 4mm |

| Accuracy | less than 0.1mm | less than 0.1mm | less than 0.1mm |

| Max. pressure | 300T | 300T | 300T |

| Max die cut speed | 7500s/h | 7500 s/h | 7500 s/h |

| Max feeder pile height | 1600mm(include pallet) | 1600mm(include pallet) | 1600mm(include pallet) |

| Max delivery pile height | 1400mm(include pallet) | 1400mm(include pallet) | 1400mm(include pallet) |

| Max.foil diameter | 250mm(vertical) 200mm(horizontal) | No | No |

| Foil width | 20-1020 mm | No | No |

| Main motor | 11Kw | 11Kw | 11Kw |

| Overall size | 7700*5200*2600mm | 6300*4600*2400mm | 7700*4600*2400mm |

| Machine weight | 18.5 Tons | 16 Tons | 17 Tons |

| Total power | 52 Kw | 16 Kw | 16.9 Kw |

Please write more details of your specific requirement, so our sales team can provide you right machine you need.

kingsungroup

kingsungroup E-mail Us

E-mail Us

PDF Download

PDF Download Video Link

Video Link