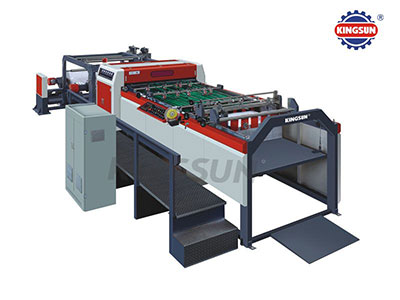

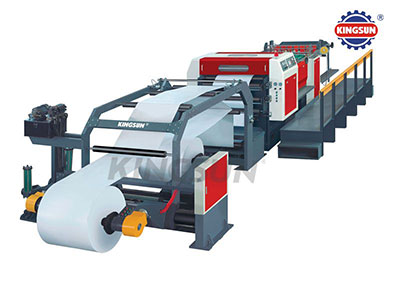

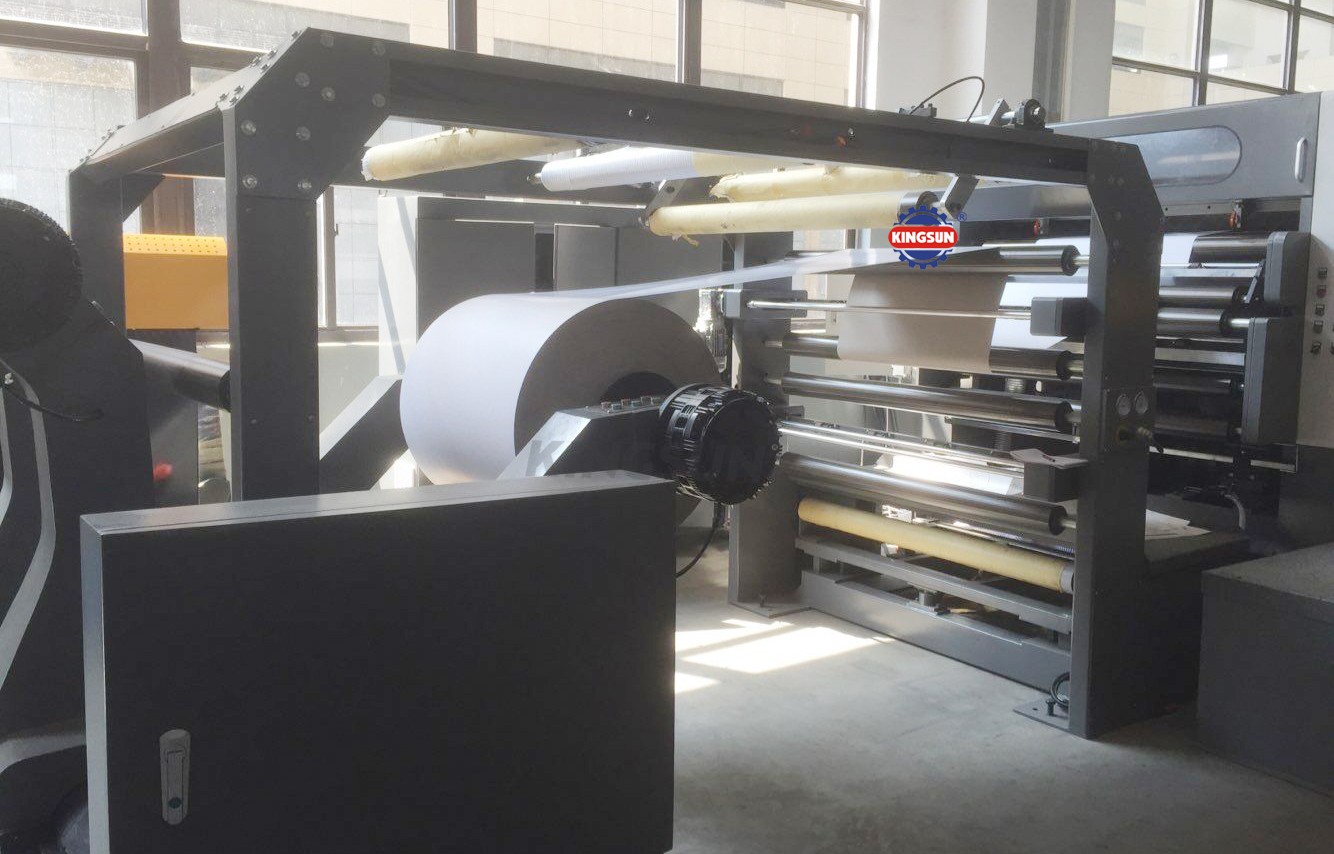

KSM series Automatic Servo Control Double Rotary Knife High Speed Paper Sheeter Machine is fit for paper roll to sheet cutting into sized paper,it is one of most advanced and high precision type of paper sheeter machine in the world. It is suitable for high precision paper size required converting company, the sheet cut paper can directly for offset printing machine.

KSM Paper Sheeter Machine can Improve Your Production Capability and Flexibility for Paper Converting!

KSM Series Servo Control Double Rotary Knife High Speed Paper Sheeter Machine is fit for paper roll to sheet cutting into sized paper,it is one of most advanced and high precision type of paper roll to sheet cutting machine in the world. This machine is excellent for thick paper converting, with features of high precison and high speed, nice cutting edge side, directly go for printing machine, so can save time and cost,greatly improve the production capacity, it is one of most ideal paper roll to sheet cutting machine for paper mill, printing house and packaging manufacturing company.

Main features:

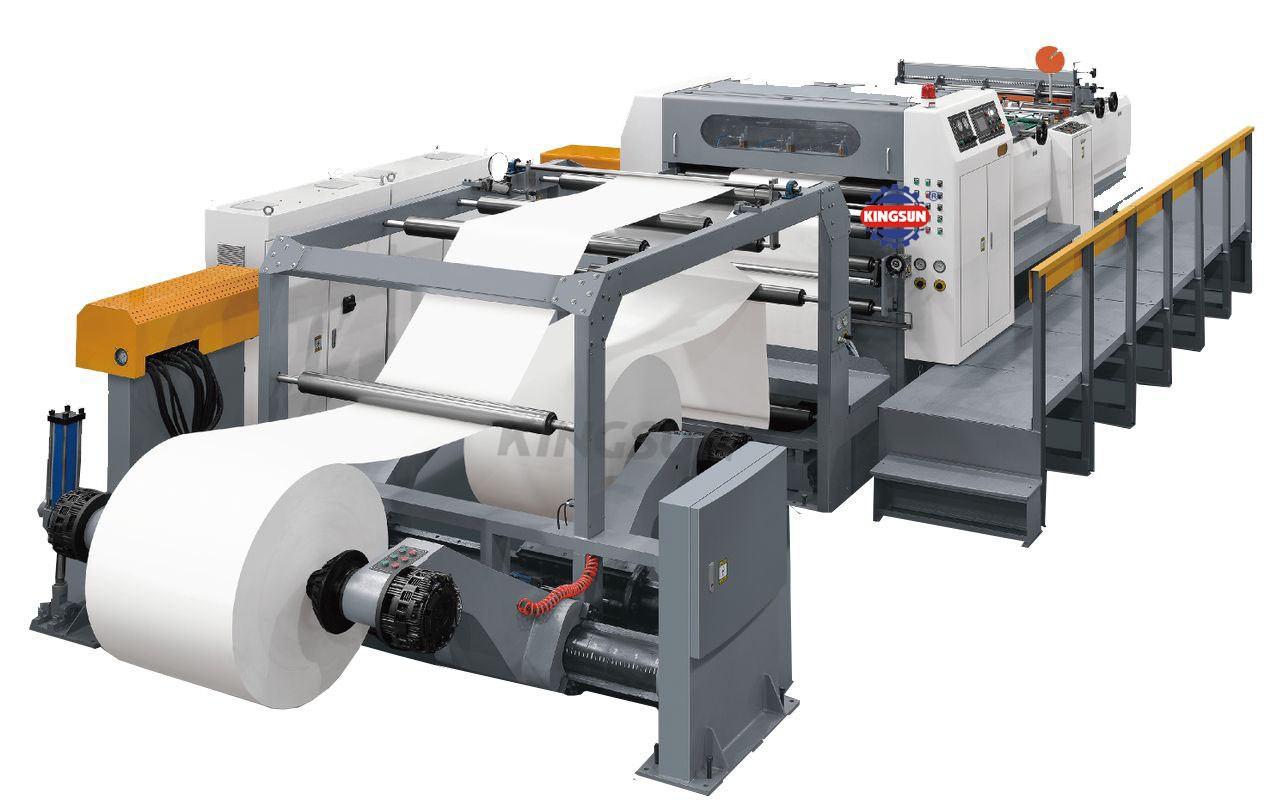

(1)Adopt nodular cast iron-QT500-7, original paper frame clamp arms casting by special technology process, thus featuring by high strength, never deformation and ensure the safety of original paper frame clamp arms.

(2)Adopt steel plate-Q335, the mainframe wallboard has precision manufacturing and high strength, thus will never-deformed.

(3)The whole machine all uses SKF\NSK Original imported bearings.

(4)The whole sheeter machine uses original parts imported from France Schneider, Japanese OMRON and Japanese SMC, etc.

(5)The conveyor belt is imported from Japan.

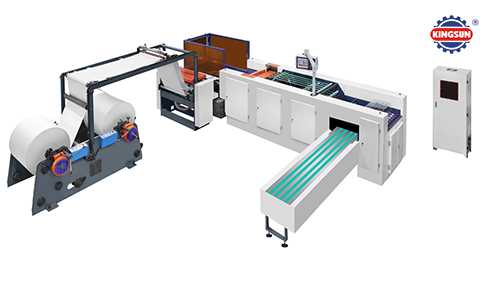

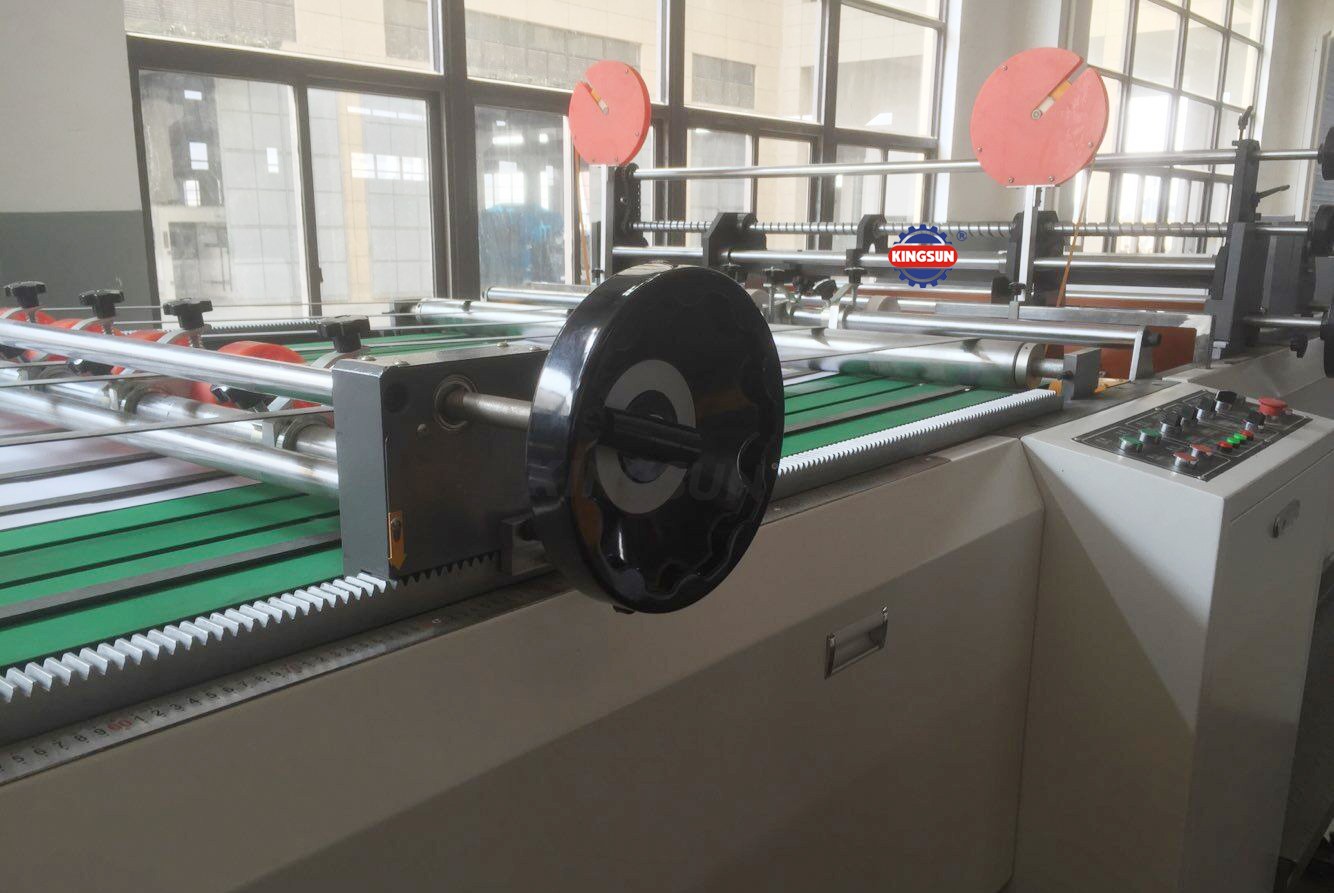

(6)Cutting accuracy reach to ±0.2mm, the highest speed of KSM series machine reaches 300 sheets/min.

(7)The back cutter is adopt Germany Ni-Cr-Mo metal steel, with high precision and will never- deforms; the knife edge is easy to adjust and calibrate.

(8)Use the automatic angle-aligning system to realize fast angle aligning of worksheet.

(9)Equipped with anti-curve automatic regulation device, ensure fast and smooth when they adjust of anti-curved paper.

(10)Paper feeding part adopts pre-pressing device, to ensure that the paper is not wrinkled.

(11)Equipped with touch-screen operation interface in both Chinese and English, or other language customzied.

(12)Adopt Taiwan AIRTAC's pneumatic components to ensure every pneumatic action performs accurately.

Main specifications:

|

Model |

KSM -1100 |

KSM -1500 |

KSM -1700 |

KSM -1900 |

|

Mode of sheeting paper |

Double rotary knife |

|||

|

Paper thickness |

60-1000GSM |

|||

|

Max roll diameter |

1500mm |

1800mm |

||

|

Max roll width |

1100mm |

1500mm |

1700mm |

1900mm |

|

Cutting length |

450-1450mm |

450-1600mm |

||

|

Form of slitting |

Two sheets |

|||

|

Cutting precision |

Cutting length≤ 1000mm: ±0.2mm, Cutting length >1000mm: ±0.1% |

|||

|

Max cutting speed |

300cuts/min |

|||

|

Max cutting linear speed |

300m/min |

|||

|

Max paper pile height |

1300mm |

1500mm |

||

|

Air pressure |

0.8MPa |

|||

|

Electric voltage |

380/220V 50/60Hz |

|||

|

Machine weight |

12000kgs |

16000kgs |

18000kgs |

20000kgs |

Paper Sheeter Machines FAQ:

1) What kind of materials can cut on this paper sheeter machine?

A: It can sheet cut paper from 60gsm to 1000gsm paper, the range thickness is most guaranteed, but if the cutting paper more than 200gsm it is the best choice.

2) Can this sheeter paper machine cut less than 60 gsm paper?

A: Usually this model mainly good for cut thick paper, if for very thin paper under 200grams,we suggest to choose single rotary knife sheeter.

3) What kind of data you need to provide before get a quotation?

A: It necessary to know: What is max roll width, paper thickness range ( gsm or thickness), how many rolls need to sheet cutting together, speed you required etc.

4) How long can you finish the paper sheeter machine production after we place the order?

A: Normally it takes 40-50 days for the sheeter paper machine production, in specail cases, we can make earlier delivery in case you have any quick delivery requirement.

5) Can you ship the machine to our factory?

A: We can ship the paper sheeter machine to everywhere around the world, the machine will be well packed and loaded in container, mainly it is go to your nearest port,but also can delivery to your factory address if there is any need.

6) What quality guarantee you provided for your sheeters?

A: Our paper sheeters have one year quality guarantee within one year after installed in buyer factory. After the warantee time, we will just charge the parts cost only minium of production cost in case need. All the machines have life-time maintenance and with free technical support.

Please write more details of your specific requirement, so our sales team can provide you right machine you need.

kingsungroup

kingsungroup E-mail Us

E-mail Us

PDF Download

PDF Download Video Link

Video Link