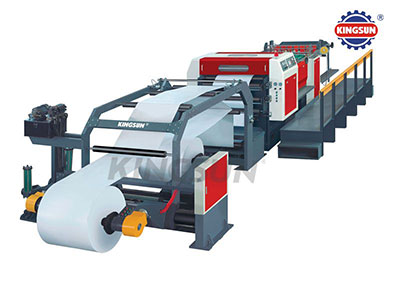

KS-A series servo control high speed rotary paper sheeter is designed for jumbo roll paper sheet cutting into required size, it is widely use for paper converters and printers for converting paper or duplex cardboard. This series paper sheeter machine is one type of high precision and most reliable function sheeter paper machine, our factory is one of the largest paper sheeter manufacturer in China.

The installation and operation of this sheeter machine is easy, it is long last series sheeters, the sheeting machines sold over 20 years still work very well and reliable in customer's factory.

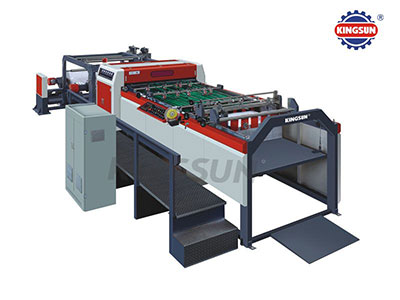

KS-A Series Servo control high speed rotary paper sheeters (Automatic sheeter paper machine)

This series servo control rotary knife paper sheeter machines are fit for jumbo roll paper sheet cut into required size, with new advanced technology from Europe and Japan, combinding with our 20+ years manufacruing experience, it becaomes most popular model paper sheeter with economic cost, it has features of high speed,flexible unwind stand unit,high production capacity and reliabel working.

It is an ideal paper sheeting machine for high speed paper converting production, widely use for packaging making industry, printing house or paper trading company etc. In case you need special size paper sheeter, please feel free to contact us, we also can custom made for your unique needs.

Main technical data:

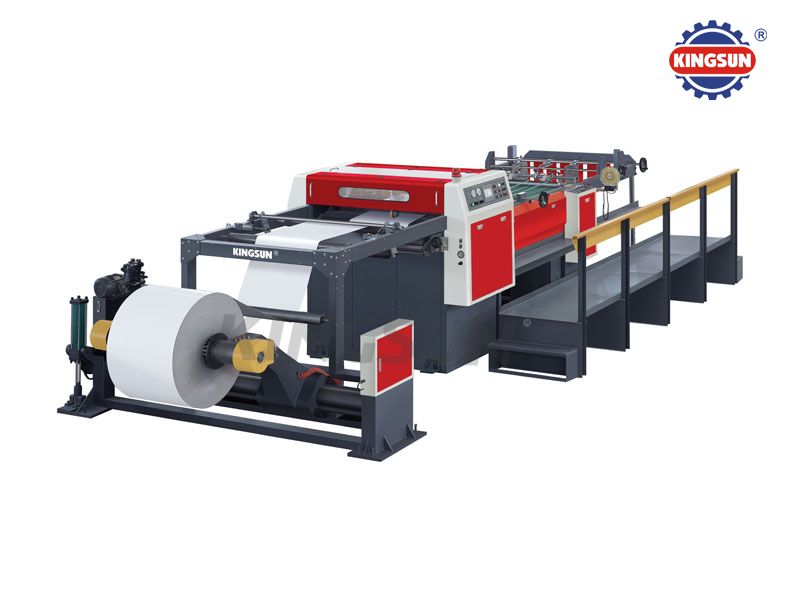

1. Paper cutting type: the up knife rotary cut, the down knife fixed

2. Range of the paper: 60 ~ 550 GSM

3. Max unwinding diameter: 1800mm (71 ")

4. Max unwinding width: 1400 mm (55 ") ( for 1400 model)

5. Cutting length: 450-1450mm

6. Paper cutting layer: 1 layer (standard)

7. Cutting accuracy: cutting length less than 1000mm: ± 0.5mm

cutting length more than 1000mm: ± 0.1%

8. Maximum cutting speed: 300 cuts / min

9. Maximum cutting linear speed: 300 m / min

10. Air source requirements: 0.8MPa

11. Design Power: AC380V/220V × 50Hz/60Hz

12. Cutting length accuracy: based on the density of paper web, the number of reels and materials. If the length less than 1000mm, the precision is ± 0.5mm, if cutting length more than 1000mm : ± 0.1%, when speed accelerating or decelerating ± 0.1%, the data is based on the cutting of correct operating procedures and stable running.(When cutting paper in one roll, the cutting length is the correct length)

13. Production output: the actual output based on the paper specific materials, paper weight, cut length, reel number, operator technique, operating conditions and so on.

Note: This series standard model paper sheeter machine is one paper reel stand, it can be added as per your request to max 6 reel stands.

Machine Features:

1) Shaftess unwinding stand: fit for 3", 6", 12" paper core. Clamp arm lifting by hydraulic cylinder. Air brake control the tention.

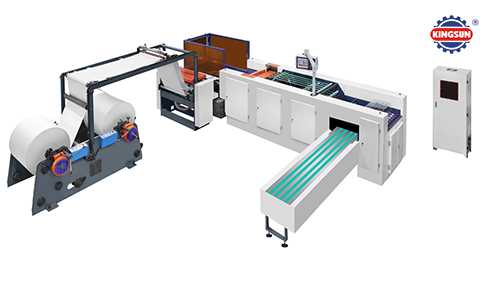

2) Web guiding: if with two,four or six rolls cutting together, it need to install the web guide, which can keep the edge side flat and smooth before cutting.

3) High precision single rotary blade cutting, designed for less cutting load and noise, and easy for setting and keep long lifespan.

4. Anti-static device: Plasma rod to eliminate the static electricity on paper. Installed in the middle of the conveyor belt.

5. Conveyoring unit: Horizontal and differential speed conveyor belt Japan imported, pressurized conveyor wheel can increase paper stability and avoid excursion.

6. Automatic meter counting and label inserter: Preset counting number on-screen and it can insert the label when reaching the preset data.

7. Automatic paper stacking unit: Hydraulic lifting paper stacker, it will automatically fall down when reaching a certain height.

8. Sheeter Machine controlling: It is designed for easy operation.Cutting length, quantity, and the total cutting quantity can be presetting in screen. Actual cutting length and cutting quantity will be display on the screen

Please write more details of your specific requirement, so our sales team can provide you right machine you need.

kingsungroup

kingsungroup E-mail Us

E-mail Us

PDF Download

PDF Download Video Link

Video Link