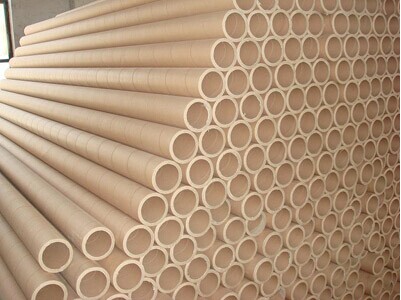

This paper tube winding machine imitates the latest model of German and French made paper core winding machine, it can make paper core range from 25mm to 250mm,the wall thickness of paper core can reach 15mm even more.

KJT-4D Four Heads Paper Tube Winding Machines

Main Features:

1.This paper tube winding machine imitates the latest model of German and French made paper core winding machine, it can make paper core range from 25mm to 250mm,the wall thickness of paper core can reach 15mm even more.

2.The way of driving system adopts helical bevel gear, it guarantees coiling with features of stable and great force.

3.Latest model of wax lubrication system is adopted, which is similar to Japan-made type, therefore, this can maintain the friction coefficient between the paper core and center-shaft stable, and more easy to control the spiral gap of paper core. This can improve the quality of paper core in an all-round way, and resolve the phenomenon of oil stain which through the oil lubricating method, so the bottom paper can keep its original features.

4.Lengthen the main beam(longer than old type),so the force of belt and paper core is well-distributed, it can improve the degree of flat of paper core.

5.Multi-layer paper rack ,it makes the multi-layer paper doesn’t need to pass through the belt, it well in line with the design of main beam and raise the quality of paper core.

6.The main beam is made od casting iron and through aging-treatment, it is durable and no-deformable.

7.The flange shaft designed for adjustable, it cooperate with the taper center-shaft and fine tuning the inner diameter of paper core.

8.The belt cylinder chromate treatment.

9.Adopts German’s high speed low resistance cutting system, the cutting surface of core is much smooth and few waste.

10.The driving system adopts gearshift, it can suitable for different kinds of paper core. If produce the thick wall paper core, you can choose the low speed. If you want to make thin paper core, you can shift to fast speed.

11.The electric control system is in conformity with International Standard, it is easy to maintain and function stable.

12.Overall dimension:5500x1100x1900mm

Features of Gluing System:

1.The tension of paper belt can be controlled and digital display, the pressure of each layer paper belt adjust steplessly, it greatly enhance the balance of gluing and controllable of strength of paper core.

2.Automatic circulating glue coating system.

3.Each paper belt has one glue plate,

4.It has electric angle adjust device.

5.The way of pass through paper belt in a horizontal way. It will be more convenient and fast.

6.The whole design of gluing system is in line with principle of Ergonomics.

7.The gluing plate and tension control board are all adjustable, the fine tuning of angle of paper belt is more convenient.

8.Easy to clean the glue plate and avoid to block.It is also easy to change the glue and good for storage of the glue.

9.Overall dimension:2500x1100x1900

Features of paper rack unwinding system :

1.Electric device for paper belt angle adjustment.

2.Electric paper lifing system,it greatly improve the efficiency, and suitable for large diameter paper roll.

3.Whole entirety paper rack,it can adjust the angle to its optimiun at one time.

4.It adopts double-station design,and no need to low the speed and avoid to affect the quality of paper core.

5.Each guide wheel for paper belt has installed bearing.It can decrease the conveying resistance.

6.Each guide wheel can adjustable in horizontal direction.

7.Overall dimension:6500x1400x2860mm

Total power:13.2kw

Main Specification:

Inside diameter: 25 -200mm

Max thickness: 15mm

Speed: 15m /min

Length: 1 -4m (custom-built)

Power of main machinery: 11kw

Power of cutting machinery: 2.2kw

Power of circular-blades cutting: 0.75kw(non-assembly)

Power of dust extraction: 0.75kw(non-assembly)

Power of wax-lubrication machinery: 0.8kw

Size: 5100 x 1100 x 1900(mm)

Note: All the paper tube winding machines can be special made according to your actual paper tube production, so please let us know your paper tube details: Max. and Min. of outside diameter, inner diameter, wall thickness, cutting length, how many layers ( or paper thickness), for which kind of products use, any special requirements etc, then our engineers and sales will work out a best solutions for you ASAP.

Please write more details of your specific requirement, so our sales team can provide you right machine you need.

kingsungroup

kingsungroup E-mail Us

E-mail Us

PDF Download

PDF Download Video Link

Video Link