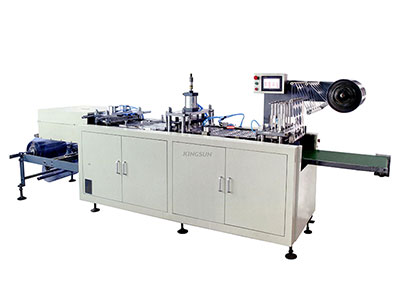

JBZ-A12 paper cup forming machine is a multi-station automatic machine producing single-sided PE coated drink cups, ice cream cups or conical vessels of other food through continuous process of automatic paper feed, medium welding tube forming

JBZ-12A Paper cup forming machines

JBZ-A12 paper cup forming machine is a multi-station automatic machine producing single-sided PE coated drink cups, ice cream cups or conical vessels of other food through continuous process of automatic paper feed, medium welding tube forming, cup rabbet lubrication, body paper rush, bottom pressing, heating, bottom knurling, upper mouth hemming, binding, unloading and finished product stacking.

Main Features:

1.Precise box type indexing cam structure, the parts all adopt standard production, have high generality and good exchange performance, and facilitate equipment maintenance.

2.The paper holder is provided with paper feeding detection function, so that it will alarm automatically when the paper is less than a certain amount. (optional according to the demand of the customer)

3.The heat seal barrel forming part is provided with non-cup-barrel detection, alarming and sopping functions, which enhance the automation degree of the machine. (optional according to the demand of the customer)

4.The bottom-punching part is changed into mechanical probe type detection which ensures the detection precision and the pass rate of finished products.

5.The machine adopts high-position stopping device, so that the machine always stops at the highest point, the mold and the heating furnace are fundamentally separated and the paper cup is prevented from being burned.

6.The large vertical shaft of the machine adopts oil tank lubricating, which ensures that the vertical shaft is soaked in the lubricating oil and is not damaged after long-time running.

7.The company has improved the rolling part, the bottom punching part, the heating part, the rolling wheel and paper cutting, being capable of producing thick paper which is more than 300g/㎡, and is free of water seepage and water leakage.

Main specifications:

|

Model |

JBZ-A04 |

JBZ-A12 |

JBZ-A16 |

JBZ-A22 |

|

Specification of paper cup |

2oz,4oz,4.5oz,6.5oz ice cream paper cup |

6oz,8oz,9oz,12oz |

8oz,9oz,12oz,16oz |

8oz,9oz,12oz,16oz |

|

Paper material |

Single-sided PE coated paper |

|||

|

Outer diameter of cup rabbet |

50-80 |

50-95 |

50-95 |

50-95 |

|

Outer diameter of cup bottom |

35-70 |

35-70 |

35-70 |

35-70 |

|

Cup height |

30-60 |

50-120 |

80-150 |

100-175 |

|

Bottom depth |

≤10 |

≤10 |

≤10 |

≤12 |

|

Rated productivity |

40-50pcs/min |

35-45pcs/min |

35-40pcs/min |

|

|

Power supply |

380V 50Hz |

|||

|

Total power |

5KW |

6KW |

||

|

Weight |

1600Kg |

1900Kg |

||

|

Packing size(L*W*H) |

2800×1350×1760mm 730×600×1100mm |

3000×1350×1900mm 730×600×1100mm |

3300×1450×2000mm 730×600×1100mm |

|

Please write more details of your specific requirement, so our sales team can provide you right machine you need.

kingsungroup

kingsungroup E-mail Us

E-mail Us

PDF Download

PDF Download Video Link

Video Link