This series computer control high speed rotogravure printing press is one of most advanced type gravure press in China which adopts latest technology from Japan and Europe.Main electric parts use world famous brand.

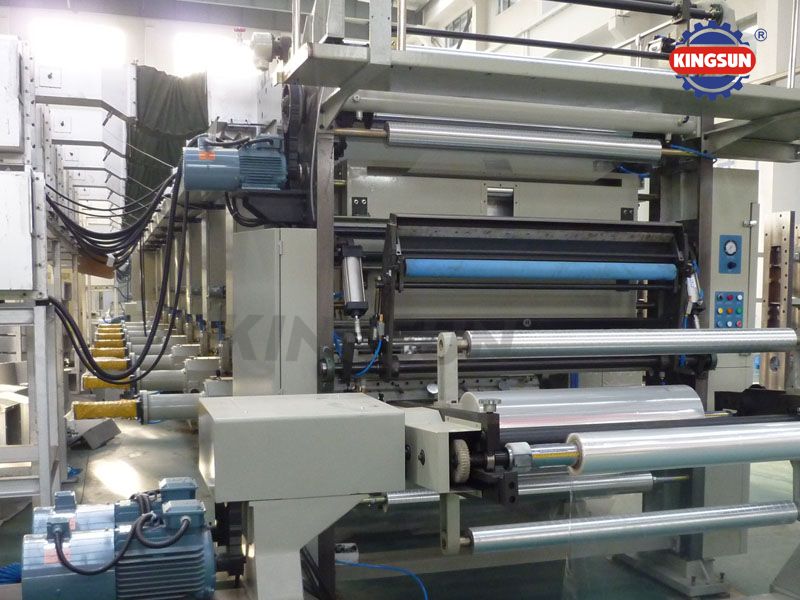

KYJZ-10-1050 Computerized high speed rotogravure printing presses

Introduction of KYJZ series:

This series computer control high speed rotogravure printing press is one of most advanced type rotogravure printing press in China which adopts latest technology from Japan and Europe. Kingsun brand gravure printing machines choose the world top level electric components such as Siemens,Yaskawa,ABB, Mitsubishi, Schneider,mechanic parts such as NSK,FESTO,so make the printing press at higher quality and relialbe function.It has features of high working efficiency and energy saving,stable color register and high accuracy,user friendly operation and easy for maintenance.It is ideal rotogravure printing equipment for flexible packaging coverting industry.This series rotogravure presses are in line with world top level technology.

7 motors PLC automatic control, HMI, precision for tension control, ARC system, video camera checking.

Technical Specification:

|

Printing color |

10 color |

|

Max. printing width |

850/1050/1250mm |

|

Max. speed of machine |

220m/min |

|

Max. speed of printing |

200m/min |

|

Plate cylinder width |

660mm-1050mm |

|

Plate cylinder diameter |

120-300mm |

|

Overprinting accuracy |

±0.1mm(Longitudinal and transverse) |

|

Machine wall body thickness |

75mm |

|

Diameter of unwind and rewind units |

600mm(can be special made) |

|

Unwind and rewind structure |

Double arms double shafts turret |

|

Inking form |

Circulation inking system |

|

Film tension control |

Seven motors close loop,four dancing roller control |

|

Splicing method |

Automatic non-wastage splicing with non-stop |

|

Drying method |

Electric or gas |

|

Air source Minimum pressure |

0.6Mpa |

|

Main motor power |

22kw |

|

Size of overall machine |

22400L ×5400W×3500H |

|

Machine weight |

About 58000kg |

|

Electricity power |

380V±10%,50Hz three phase |

Note: Number of rotogravure color unit as per your requirement,optional unit such as EPC, corona treatment,viscosity controller,turn bar,bigger diameter are all welcome for tailer made.

Please write more details of your specific requirement, so our sales team can provide you right machine you need.

kingsungroup

kingsungroup E-mail Us

E-mail Us

PDF Download

PDF Download Video Link

Video Link