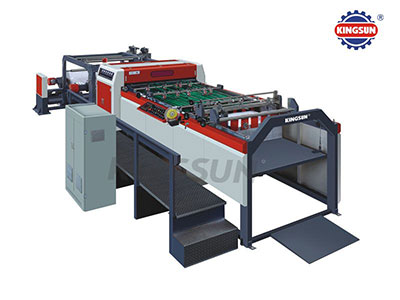

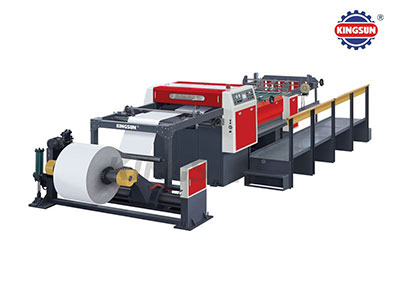

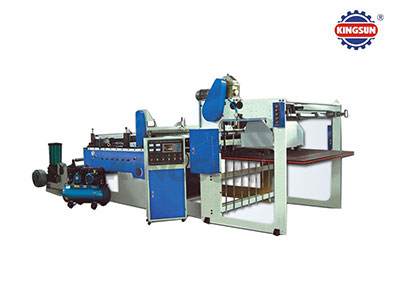

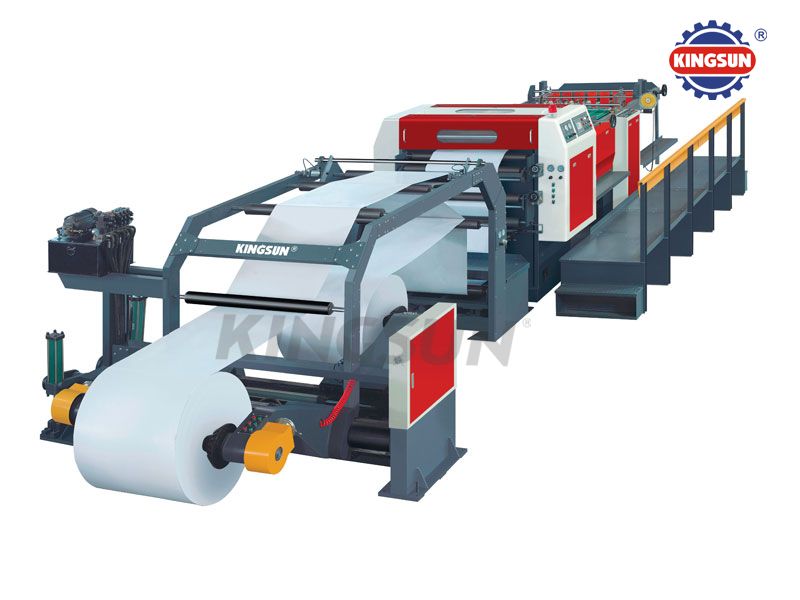

KS-B series servo control high speed rotary paper sheeter is mainly use for rotary knife sheeting the big jumbo reel paper or cardboard into required size sheet, it is good for medium and large capacity paper converting company. With features heavy duty and more reliable machine body and controlling, with one rotary knife cutting, especially excellent for thin paper sheet cutting with high speed working.

KS-B Series Servo control high speed rotary knife paper sheeter machine (Automatic paper roll to sheet cutting machines)

This KS-B series servo control high speed rotary paper sheeter machine is mainly use for rotary knife sheeting the big jumbo roll paper into required small size sheet, it is for big capacity paper converting company. It is one of most advance type of paper sheeter machine or paper roll to sheet cutting machine, and with higher grade model which compared with KS-A series paper sheeter machine.

Main technical data:

KS-1700B (standard configuration) :

1. Model of cutting paper: the up knife rotary cut and the down knife is fixed;

2. Thickness of cutting paper: 60-550GSM;

3. Max. unwinding diameter: 1800mm (71”)

4. Max. paper-cutting width: 1700mm (76”)

5. Cutting length range: 450-1450mm

6. The format of slitting: 2 sheets

7. Cutting precision: cutting length is < 1000mm : +0.5mm;

cutting length is > 1000mm: +0.1%;

8. Max. cutting meter speed: 350m/min;

9. Max. cutting sped: 350cuts/min;

10. The request for air compressor: 0.8Mpa;

11. Power consumption: 380V/220V,60Hz/50Hz;

12. The accuracy of the cutting length: It is based on the paper density, number of volumes;

material of the roll paper, also base on the stabilized operation and the right processing when cutting off,

the cutting length is < 1000mm, the accuracy is : +0.5mm;

the cutting length is >1000mm, the accuracy is: +0.1%

when speed up or down.(cutting paper is one roll, the cutting length of the paper is the right length).

13. Production capacity: the actual output is based on the material, weight, cutting length, number of rolls paper, the operator technology, the operating conditions of the paper.

14. Paper sheeting machine width: 1400mm, 1700mm, 1900mm.

15. The unwinding reel stand standard model is two, you can add additional unwind if request.

Paper Sheeter Machine FAQ:

1) What kind of materials can sheet cut on this kind of paper sheeter?

A: It can sheet cut paper from 60gsm to 550gsm paper, the range is most guaranteed, in fact the range could be wider on real production.

2) Can this sheeter machine cut more than 550gsm paper?

A: Every machine has its own limitation when design, usually this model mainly good for cut thin paper, if for very thick paper we suggest to choose twin-rotary-knife sheeter.

3) What kind of data we need to provide before get a quotation?

A: It necessary to know: What is max roll width, paper thickness range ( gsm or thickness), how many rolls need to sheet cutting together, speed you required etc.

4) How long can you finish the paper sheeter production after we place the order?

A: Normally it takes 35-45 days for the sheeter machine production, in specail cases, we can make earlier delivery in case you have any quick delivery requirement.

5) Can you ship the paper roll to sheet cutting machine to our factory?

A: We can ship the paper sheeter to everywhere around the world, the machine will be well packed and loaded in container, mainly it is go to your nearest port,but also can delivery to your factory address if there is any need.

Please write more details of your specific requirement, so our sales team can provide you right machine you need.

kingsungroup

kingsungroup E-mail Us

E-mail Us

PDF Download

PDF Download Video Link

Video Link